Avoiding Complacency about Sugarcane Aphid

This tip was provided by:

Calvin Trostle, Extension Agronomy, Lubbock, 806-746-6101, ctrostle@ag.tamu.edu

Central, North & High Plains

Avoiding Complacency about Sugarcane Aphid

In his June 30 “Rolling with Bowling” entomology newsletter, Dr. Robert Bowling, Extension entomologist, Corpus Christi (361-265-9201, robert.bowling@ag.tamu.edu ) summarized 2016 sugarcane aphid dynamics (or lack thereof) in South Texas. There was modest pressure in some area, but in many if not most instances SCA numbers though perhaps high early, these populations reduced greatly and were no longer an issue. The newsletter will be posted shortly at http://ccag.tamu.edu/newsletters/ (call or e-mail if not yet posted).

Last year SCA showed up in the High Plains in late June. This year there was overwintering SCA in three cages and a patch of Johnsongrass in the central and lower South Plains, but currently there are no reports of SCA any closer than the San Angelo area (which was a new discovery about a week ago). Sorghum farmers everywhere, however, must not become complacent. Scouting it still required. Yes, an eventual report of SCA south and east of you 50 miles or 100 miles may help you understand movement and add impetus to your scouting, but SCA movement itself is hard to predict. Tuesday night, July 5, I drove from Dallam Co. home to Lubbock in the face of a stiff south-southeast wind that was over 30 mph some of the time. This is just the kind of wind for many hours that can enable airborne winged SCA adults to travel significant distances.

Please keep in touch with your local IPM agent, regional Extension entomology specialist, and networks like Texas Sugarcane Aphid News (http://txscan.blogspot.com) to keep abreast with up-to-date developments.

For a review of SCA and its management refer to the May 27 Sorghum Insider “Sorghum Tip,” available at http://texassorghum.org/2016-agrilife-extension-entomology-sugarcane-aphid-information.html

Last week, we received this comment from a reader regarding moisture levels in grain sorghum at harvest after posting our last Sorghum Tip:

It should be noted that most moisture and drying discounts reflect the loss in weight due to moisture in the grain and grain harvested at higher moisture ie 16% and dried to 14% or less will be prettier and grade better. As you reflect in the article grain harvested at under 14% cost producers and it should be noted there is significant loss from cracks and lights being blown out of a combine at these lower moistures and this can cost producers significantly. I think ideally a producer should start harvest where he can average 14% harvested grain at the finish. Therefore starting at maybe 16% to know that when he finishes he will be at 14% and not 10% or 12% moisture.

Potential Income Losses in Harvesting Dry Sorghum Grain

This tip was provided by:

Calvin Trostle, Extension Agronomy, Lubbock, 806-746-6101, ctrostle@ag.tamu.edu

Statewide

Potential Income Losses in Harvesting Dry Sorghum Grain

The standard moisture for sorghum grain at harvest time is 14.0%. If your grain sorghum moisture is above 14.0% you will be docked for the moisture. If you are too much above standard moisture content for sorghum grain your delivery point may reject the grain, especially if they do not have drying capacity.

Common incentives that drive harvesting grain sorghum across Texas as soon as possible include minimizing potential storm and wind damage every day the crop remains in the field; muddy conditions that delay harvest if it rains again; risk of lodging; minimizing late-season weed issues; possible double-cropping scenarios where the sooner the next crop is in the more time it has for growth and maturation.

But there is another potential downside to harvesting dry sorghum—or any grain—when the crop remains in the field, further drying to well below standard moisture content. Namely, the drier the grain, the more grain it takes to make a 100-lb., or cwt., pay unit. In effect, being able to deliver sorghum grain as close as you can up to 14.0% enables you to “sell water.” Conversely, as noted above, if grain moisture is above 14.0%, you don’t get paid—you get docked.

But how much is the potential income reduction in selling dry sorghum grain that perhaps you could have harvested sooner at somewhat higher moisture? Is it a little? Is it a lot?

Below is a table for sorghum grain with different moisture contents at a range of grain sorghum prices ($/cwt.) to help you understand what the potential for a reduction in your effective per-cwt. sorghum price is as you sell further and further below 14.0%. A link to this table and a calculator, entitled “Sorghum Grain Moisture Calculator—Potential Income Loss” is posted on the sorghum page at

http://lubbock.tamu.edu/programs/crops/sorghum/ (and also soon in the Harvesting/Handling section at http://varietytesting.tamu.edu/grainsorghum/index.htm).

Estimate your potential reduction in effective per-cwt. price for grain sorghum <14.0% moisture from the above table. Access the calculator to determine reduction in potential income per cwt. with your actual %moisture and market grain price ($/cwt.). Furthermore, with grain yield (actual or estimated) you can also calculate your potential reduction in income per acre and per field or farm.

Example:

You harvested grain sorghum at 11.0% moisture at a price of $6.50/cwt. From the table (or the calculator in the online file) you find that you have effectively reduced your price $0.22/cwt. relative to 14.0% moisture. At 5,000 lbs. per acre, this is a loss of potential income of up to $10.96 per acre. And if you have 400 acres of sorghum, then you could have “sold water” and preserved up to $4,382 of income.

Weather, availability of harvest equipment, etc. will dictate when you can actually harvest grain sorghum, and no, you can’t hit 14.0% most of the time. But if by more timely harvest you can sell grain sorghum at 12.0% moisture instead of 10.0% moisture, in the above example you can preserve some income (improve $0.14/cwt.; $7.05/acre; and $2,823 for this 400 acres of grain sorghum). The difference is enough to factor in your harvest management decisions to put that money in your pocket.

High Plains

Late-Plant Grain Sorghum

For producers looking at late-planted grain sorghum in the Texas High Plains consult the updated guide “2016 Alternative Crop Options after Failed Cotton and Late-Season Crop Planting for the Texas South Plains.” This includes needed information for grain sorghum and other crops for late planting, including last recommended planting dates based on your location, sorghum hybrid maturity, or other crops.

Wet Weather and Nitrogen Losses from Soil

This tip was provided by:

Ronnie Schnell, Cropping Systems – Statewide, College Station, ronschnell@tamu.eduStatewide

Statewide

Wet Weather and Nitrogen Losses from Soil

Nitrogen losses from soil following fertilizer applications to crops can be difficult to quantify after periods of wet weather. How much nitrogen was lost and how much does it vary spatially? If significant amounts are lost, yield reductions are likely. Answering these questions is critical when considering supplemental or “rescue” applications of nitrogen. Understanding nitrogen loss pathways will help to estimate nitrogen loss.

Nitrogen is lost from soil by four main pathways: denitrification, runoff, leaching and volatilization. When excessive rainfall and saturated soil conditions occur, denitrification and leaching are the greatest concerns. Many factors can affect denitrification and leaching losses, including soil texture, fertilizer type and rate, placement and timing, soil temperatures and the amount of rainfall received (duration of saturation).

Nitrate nitrogen (NO3-N) is required for nitrogen to be lost from soil by these two processes (leaching and denitrification). Understanding how much nitrate-nitrogen is in the soil is the first step to estimating potential losses. Fertilizer products may contain nitrogen in ammonium (NH4) and nitrate (NH3) forms. UAN (32-0-0) has about 25% of the total nitrogen as nitrate. Ammonium forms of nitrogen are rapidly converted (oxidized) to nitrate by soil bacteria in a process known as nitrification. The process is faster with warm soils. Most of the ammonium may be nitrified within several weeks under warm conditions. Nitrification inhibitors can be used to delay this process. Saturated soils (oxygen depleted) will also halt the nitrification process. Therefore, timing and source of nitrogen fertilizer plus the use of nitrification inhibitors will affect how much nitrogen is nitrate form. Nitrogen fertilizer applied several weeks or more before excessive rainfall without nitrification inhibitors is likely largely in nitrate form. This does mean it is lost but has the potential to be lost.

Coarse textured soils (sandy) are much more susceptible to leaching of nitrate below the rooting zone of the crop. Finer textured soils (clay) are susceptible to leaching and denitrification, although leaching potential is substantially lower compared to sandy soils. Low infiltration rates and ponding can result in extended periods of saturation. This will increase the potential for denitrification losses. As soil oxygen is depleted, some soil microbes will switch to nitrate for survival, releasing the nitrogen in gaseous forms that escape into the atmosphere. Some estimates suggest 2 to 5% of the soil nitrate-nitrogen can be lost per day of saturated conditions. The total loss will depend on nitrate available in soil, number of saturated days and temperature. Actual losses can vary widely depending on these factors.

Determining potential nitrogen losses in-season is difficult. Deciding if and what amount of additional nitrogen to apply can be challenging. If you have reason to believe significant nitrogen has been lost, there are several considerations when planning supplemental nitrogen applications. First, ensure that plant stands/populations are adequate for expected yield goals. Next, consider the growth stage of the crop. Applying nitrogen closer to growing point differentiation will improve yield response (see previous tips). However, if panicle initiation has passed but conditions were favorable during this period, significant yield potential may exist yet. Some yield loss can be expected with later applications (pre flowering) but it is important to capture yield potential that does exist. Finally, consider grain price and nitrogen cost in combination with expected yield response. Applying 100 lbs/acre of urea (46 units of N) will cost about $19/acre ($0.42/ lb of N) plus application cost. With grain at $6.50/cwt, you need about 300 lbs/acre of grain to cover the fertilizer cost. Yield response to N fertilizer under ideal conditions is 100 lbs of grain for every 2 lbs of available nitrogen per acre (over 2,000 lbs of grain per acre in this example). With late applied fertilizer, yield response will likely be lower but may be profitable yet.

If plants have been severely affected by wet conditions, this can result in damaged root systems, reduced or delayed tillering, lower leaf area and reduced yield potential. Response to additional nitrogen is unlikely. Extended periods of stress (saturated soils) at earlier growth stages (3-5 leaf) will have greater impact compared to later growth stages (post flowering). Carefully evaluate the crops recovery once soil conditions improve before considering supplemental nitrogen applications.

2016 AgriLife Extension Entomology Sugarcane Aphid Information

This tip was provided by:

This Sorghum Tip from Extension Entomologist Dr. Ed Bynum, Amarillo, directs sorghum growers in the Texas High Plains to AgriLife Extension entomologist guidelines developed for the region. These efforts are coordinated by Dr. Bynum, Amarillo, (806) 677-5600, ebynum@ag.tamu.edu, and Dr. Pat Porter, Lubbock, (806) 746-6101, pporter@ag.tamu.edu in conjunction with the five Extension IPM agents that each cover 2 or 3 counties in the South Plains (based in Lamesa, Brownfield, Levelland, Lubbock, and Plainview)

High Plains

2016 AgriLife Extension Entomology Sugarcane Aphid Information

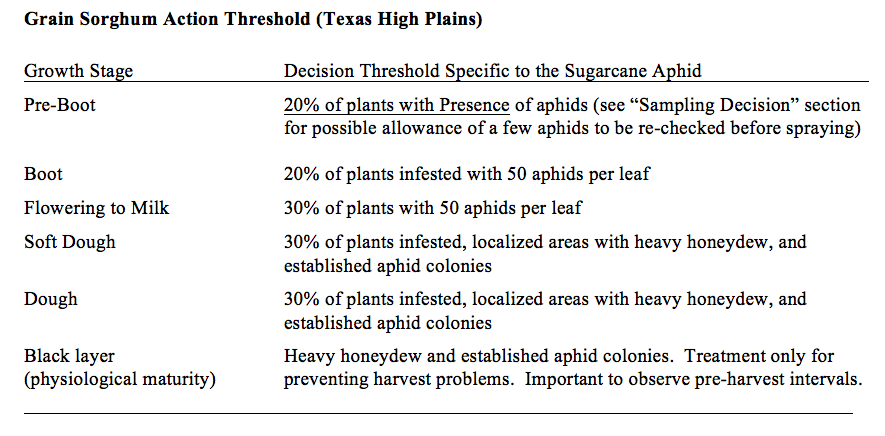

The March 10 Sorghum Tip summarized sugarcane aphid control recommendations from Dr. Robert Bowling for SCA in South and Central Texas. In this edition, High Plains sorghum growers are directed to a different set of SCA control recommendations for the High Plains region. Compared to South & Central Texas guidelines, the initial action thresholds are lower for the Texas High Plains.

If you have last year’s thresholds on hand in the High Plains, discard them and replace with the information resources below.

Since Dr. Bowling’s update, SCA has been confirmed to have overwintered on Johnsongrass in at least three counties in the High Plains (Dawson, Lubbock, Hale), but IPM agents based in Lamesa & Garden City currently have no reports of SCA on commercial sorghum.

You may access the current statewide AgriLife sugarcane aphid management guide at http://www.texasinsects.org/sorghum.html In addition to information on SCA identification, scouting, and insecticides, note the High Plains specific information found on pages 4-5. These High Plains specific guidelines are also published at http://lubbock.tamu.edu/files/2016/03/ENTO-047.pdf (ENTO-047, “2016 Texas High Plains Sugarcane Aphid Management Guide”; you can get laminated cards from your county Extension office or order from http://agrilifebookstore.org )

Overall Texas High Plains AgriLife Extension entomology suggestions for managing SCA follow these six principles:

Primary Options to Reduce Potential SCA Damage on Grain Sorghum

1) Plant outside the normal window {Early planting, e.g. late April in the South Plains to reduce risk of infestation in whorl stage, late planting in mid-summer will have a higher risk of infestation in whorl stages, but beneficial insect populations may be increasing.}

2) Use seed insecticide treatments. {This might add up to ~$50/bag for seed, but that is still less than $2.50/acre in dryland. Entomologists have noted that you should anticipate at least 30 days of some protection with any of the insecticide seed treatments.}

3) Plant “resistant” hybrids (talk to companies). {All sorghum hybrids are susceptible to SCA at some level, and AgriLife statewide has conducted little research yet on commercial hybrids. (United Sorghum Checkoff Program has summarized a list of what companies believe is their most tolerant material, see http://www.sorghumcheckoff.com/newsroom/2016/03/28/sugarcane-aphid/ )}

4) Spray promptly at threshold. {IPM agent Kerry Siders has noted that a good first shot may eliminate the need for a second spray.}

5) Re-spray the field as needed.

6) Preserve biological control—your best friend.

Additional High Plains SCA management tip sections in ENTO-047 include:

- First Detection: Is the field at risk?

- Sampling Decision

- Control Options after First Application

- Forage Sorghum Management

For further information on sugarcane aphid in the Texas High Plains and beyond follow the online Texas Sugarcane Aphid News at http://txscan.blogspot.com

Nitrogen Fertilizer Timing for Grain Sorghum

This tip was provided by:

Calvin Trostle, Extension Agronomy, Lubbock, 806-746-6101, ctrostle@ag.tamu.edu

Statewide

Nitrogen Fertilizer Timing for Grain Sorghum

In the last Sorghum Tip I discussed the nitrogen requirement for grain sorghum production, which is different than how much N fertilizer you may apply. A field may have N credits, most likely from soil test nitrate-nitrogen, which a Texas A&M AgriLife soil test will credit 100% to you grain sorghum N requirement.

Nitrogen fertilizer timing for grain sorghum can involve pre-plant application, sometimes well in advance of cropping (especially if using anhydrous ammonia, which is often cheaper per unit of N) and pop-up fertilizer (in-furrow) or starter N (placed near the seed). Each have their place though conditions like the potential for water-logged soils and the time before planting can reduce efficiency for pre-plant applications. See the Texas sorghum production guides below for information about safe use of at-plant N to ensure that toxicity or fertilizer salts do not hinder germinating grain sorghum and seedling growth.

For in-season application of grain sorghum, the key reference point that guides timing of N application is the changeover of the growing point from producing another leaf to initiating the head (Fig. 1). In wheat (the same botanic family of grasses as grain sorghum), this generally occurs just before jointing, which you can see in wheat. But in grain sorghum there is nothing visual externally on the plant that signals this is occurring. Generally, this occurs about 30 to 35 days after planting.

Fig. 1. The growing point of grain sorghum after differentiation from leaf production to developing panicle, or head. This process initiates about 30 days or so after germination. In this image there is likely at most 2 days’ difference from left (early) to right. Spikelet number and potential seeds per spikelet—both important components of yield potential—are being determined for each head over a 7 to 10-day period.

Once growing point differentiation (GPD) occurs, the developing head must not be limited in needs for sufficient nitrogen (or water!), lest you cap your potential spikelets and seeds per spikelet, thus limiting your yield potential. Once GPD concludes you cannot increase spikelet number and seeds per head.

Historical guidelines from Texas A&M, Kansas State Univ., etc. have suggested that side-dress N fertilizer applications be completed by about a month after planting to meet your crop’s targeted N requirement. This can be a substantial amount of N for larger yield goals. Though all remaining N is not needed right then at GPD, in-season N applications were generally only made once, so it was necessary to apply the remainder of your N fertilizer soon.

Today, particularly where N fertilizer applications may be conveniently supplied by dissolving in irrigation water, some producers may elect to withhold a portion of their in-season N fertility after GPD to spread out the N application and perhaps increase nitrogen utilization efficiency. This could be up to 20% or so (an estimate on my part) of the N, but I would recommend that all remaining N be on the field by early boot stage. This would be within 50 days of planting for a medium-early maturity hybrid and about 60 days for a medium-long maturity hybrid. Kansas State Univ. research suggests that by the time late boot stage occurs 70% or more of grain sorghum’s required N will already be in the plant.

Further Information:

You can read additional information on several aspects of nitrogen fertility for Texas grain sorghum from the fertility sections of the West Texas and the South & Central Texas editions of United Sorghum Checkoff Program’s production guides, on the web at http://sorghumcheckoff.com/farmer-resources/grain-production/ The information is similar in both guides, which were prepared by AgriLife Extension staff.

Nitrogen Fertility Guidelines for Grain Sorghum

This tip was provided by:

Calvin Trostle, Extension Agronomy, Lubbock, 806-746-6101, ctrostle@ag.tamu.edu

Statewide

Nitrogen Fertility Guidelines for Grain Sorghum

In our four years of compiling Sorghum Tips, we should have addressed basic N requirements for grain sorghum long ago. From the Sorghum Tips archive at http://texassorghum.org/sorghum-tips, in 2012 we did discuss 1) fully crediting 100% of your soil-test nitrate-N down to 24” and the use of Texas A&M AgriLife’s Profile Soil Sample Information Form (Nov. 7, or page 7 of archive), and 2) the full N credit you can take for any nitrate-N in your irrigation water (Dec. 4, or page 6 of archive).

But what about the straight-up, season-long N requirement for grain sorghum?

Texas A&M AgriLife’s long-time fertility goal based on soil fertility research is tied to your yield goal:

2.0 lbs. of actual N per 100 lbs. of yield goal

This is a helpful rule of thumb—for planning purposes—for your N requirement. Therefore, if you have a 5,000 lbs./acre yield goal, then the N requirement is 100 lbs. of N per acre, e.g.:

2.0 lbs. N/cwt. X 50 cwts. = 100 lbs. N/acre

This is not the fertilizer N requirement as there are credits you may claim against the total required N. In Texas A&M AgriLife these recommendations include:

- Soil nitrate-N in your surface soil sample (usually 0-6”, sometimes 0-8”). If you have 7 ppm nitrate-N in the top 6”, that is equivalent to 14 lbs. N per acre. (Each 6” deep layer of soil is about 2,000,000 lbs. of soil; thus for each 1 ppm nitrate-N, you have 2 lbs. of nitrate-N.)

- Sub-soil nitrate N (if you have the data, see #1 above). For each 6” of soil below the six-inch depth, 1 ppm nitrate-N equals 2 lbs. of nitrogen per acre, a credit against the full N requirement. For example, you have a sub-soil test sample of 6-18” deep at 4 ppm nitrate-N, then the credit determined, calculated as two 6-inch layers, is:

2 soil layers over an acre X 4 N (from soil test ppm) X 2 (ppm conversion factor) = 16 lbs. N/acre

- If you irrigate, you could also take a credit for any nitrate-N in the irrigation water (see #2 above).

- Are there other possible N credits? In Texas we don’t claim any, but a farmer sending a Kansas soil sample to Kansas State’s soil test lab will answer questions for soil texture, previous crop (if legume), and soil organic matter. Each of these will slightly alter a KSU recommendation.

The full example—

For the 5,000 lbs./A yield goal…

Fertilizer N to apply = N requirement – soil test N (0-6”) – subsoil test N (below 6”)

70 lbs. N/acre = 100 lbs. N/acre – 14 lbs. N/acre – 16 lbs. N/acre

What this example does not address—

This is the N requirement. It does not address timing (most N should be on by growing point differentiation about 5 weeks after planting), fertilizer placement, or N use efficiency. I will address these in a future Sorghum Tip. In the interim, refer to the N fertility section of your region’s USCP pocket grain sorghum production guides for Texas at http://sorghumcheckoff.com/for-farmer/production-tools/ ).

2016 Texas Grain Sorghum Weed Control & Harvest Desiccation Guide

This tip was provided by:

Calvin Trostle, Extension Agronomy, Lubbock, 806-746-6101, ctrostle@ag.tamu.edu

Statewide

2016 Texas Grain Sorghum Weed Control & Harvest Desiccation Guide

As, we have noted before in a previous Sorghum Tips, we believe your most important weed control decision for grain sorghum is always pre-plant/pre-emerge herbicide applications. Prevent weeds in the first place, and catch the escapes or other emerging weed issues later with over-the-top herbicides. For most growers a combination of atrazine and metolachlor (Dual) gives good control, but many growers will substitute propazine on sandy soils and in cotton rotations. The above document has been updated by Trostle/McGinty for use in planning your herbicide program with the active ingredients (and brand commercial names) available to your grain sorghum weed control program. View/print/download the document at http://lubbock.tamu.edu/sorghum

Is Inzen/ALS-Tolerant Grain Sorghum Available in 2016?

The prospect of over-the-top grass control in grain sorghum has been teasing us for several years. Five years ago we thought it would be here by 2014 or perhaps 2015 at the latest. We are indeed closer to this sorghum’s availability, but only one limited opportunity exists for 2016. First, this ALS-tolerant system has been named “Inzen” by Dupont, and eventually the active ingredient nicosulfuron (currently as Accent, soon as Zest) will be labeled for over-the-top application.

Currently, Pioneer does not have any hybrids that are available for growers, but Dupont licensed the technology to Advanta US, which has one hybrid (medium maturity) in their Alta Seed brand that is available on a limited basis for 2016 (one 50 lb. bag, maximum of 20 planted acres) if you are willing to partner with Advanta/Alta in a demonstration. This will involve a stewardship agreement which governs what you can do with the grain (currently only for livestock feed or ethanol—it cannot go in to the commercial grain market yet), and, for now anyway, what you can rotate to next year (not sorghum).

If you are interested in this limited opportunity with Alta seed contact an Alta dealer. You may be especially interested if you have a portion of a field where grasses are a special problem. If any TGSA members try the technology this summer, please let your county ag. agent, myself & Dr. Ron Schnell know so we can learn from your observations.

2016 Sugarcane Aphid Watch–South and Central Texas

This tip was provided by:

Robert Bowling, (361) 265-9201, Robert.bowling@ag.tamu.edu, Assistant Professor, Extension Entomology, Corpus Christi

IPM Extension agents Stephen Biles (Port Lavaca), Danielle Sekula-Ortiz (Weslaco) and Kate Harrell (Wharton)

South and Central

2016 Sugarcane Aphid Watch

Another season is upon us as farmers have begun seeding sorghum in the Lower Rio Grande Valley and Coastal Bend of Texas. Sorghum has emerged in the Valley and in some areas around Corpus Christi. Warm and dry conditions have made possible the early start to the season, especially when compared with the 2015 cropping year. How might these conditions influence sugarcane aphid infestations in sorghum?

Sugarcane aphid reproduction is favored by hot and dry conditions. Currently, sugarcane aphids have already been observed overwintering on Johnsongrass as far north as Hill County (Waxahachie). Numerous cast skins in aphid colonies have been observed around Corpus Christi up to Austin County suggesting that sugarcane aphids are maturing and producing offspring. It is possible they will start moving to sorghum early this season. What is the path forward to protect the crop from sugarcane aphid injury in 2016?

Our full first-of-the-season report on SCA for South & Central Texas is online at http://ccag.tamu.edu/sorghum-insect-pests/ Several additional SCA resources are also there including the Scout Card for use in field ID of SCA and the all-important Quick Aphid Checker to rapidly estimate the number of aphids per leaf.

Here are some additional points from our full write-up:

- Know the aphid. Use a magnifying lens for ID. If honeydew is observed, look at the underside of the leaf above. If the sugarcane aphid is found on Johnsongrass or volunteer sorghum start scouting sorghum shortly after plants have emerged.

- Start scouting sorghum early! If the planting seed was treated with an insecticide seed treatment (which AgriLife generally recommends; the cost is spread out over many acres), the crop should be protected for 30 to 45 days.

- Several grain sorghum hybrids have been identified as ‘tolerant’ to sugarcane aphid. Be aware, however, that tolerance does not equate to immunity and all sorghum fields should be scouted for sugarcane aphid. Ask your preferred seed company for their best tolerant material.

- In-season insecticide options for managing sugarcane aphid are limited. Sivanto (Bayer) is currently the most effective product labeled on sorghum and is safe to beneficial insects.

- Carrier total volume of water applied to the field is important! Complete coverage of all foliage is critical for maximum performance of an insecticide targeting the aphid. Do not apply less than 10 gallons of final volume of spray solution per acre if treating with a ground rig and no less than 5 gallons per acre if applying by air (even if the product is labeled for 3 gal/acre or less).

- DON’T BE COMPLACENT! Last year in South/Central Texas was cool and wet. SCA’s growth was slow thus insect predators to maintained sugarcane aphid populations at a low level.

Next Sorghum Tip (late Mrach): Guidelines for sugarcane aphid in the Texas High Plains, where thresholds are lower, even just the Presence of SCA in the field (in contrast to a set number of SCA per leaf for South & Central Texas).

Part II: An Important Component of Weed Control that Doesn’t Involve Chemicals, Equipment, or even Weeds. II. Your Custom Applicator

This tip was provided by:

Calvin Trostle, Extension Agronomy, Lubbock, 806-746-6101, ctrostle@ag.tamu.edu

Statewide

An Important Component of Weed Control that Doesn’t Involve Chemicals, Equipment, or even Weeds. II. Your Custom Applicator

Clear Communication is Important

In the last Sorghum Tip I discussed ensuring that your employees are clear on what needs to be done, that you cross-check with them on application practices, and even provide the means for your permanent employees to obtain their own pesticide applicator license and the training that goes with it.

Here are some key tips for working with your custom applicator:

Be clear with any commercial applicator you hire and ensure they understand what is needed and they are following label guidelines. Confirm the rate of chemical you need applied. Are their additives needed like AMS or crop oil? If so, make sure. I especially encourage farmers hiring custom application work to know what the label calls for as a minimum of carrier volume, whether by air or ground rig. Expect—require—that your applicator use the minimum labeled rate for water per acre. This is important for coverage; make sure you get what you are paying for.

Some labels unfortunately state a too-low carrier volume rate. Here are two examples that reflect different reasons why carrier volume is too low and should be increased:

- Dupont’s Prevathon, which better enables sorghum growers to attack worms in the whorl is labeled in Texas for 2 gallons per acre for aerial application. Even Dupont staff in Texas disagree with this. It needs to be at least 3 gallons per acre, and probably more for optimal coverage. Unfortunately, since this is the labeled rate your custom applicator may balk without you paying more if you want 5 gallons per acre. This is a dilemma, but if you are serious about achieving good insect control then carrier volume must be considered. A poor application may require a second application.

- Transform for sugarcane aphid. If this insecticide becomes labeled again for use, Texas A&M AgriLife entomologists are in wide agreement that coverage is critical. The labeled rate for aerial application for Transform is 3 gallons per acre, but our entomologist agree this is a situation with SCA that you need to apply 5 gallons by air (or 15 or more gallons/acre by ground vs.; 5-10 gpa is labeled). So this is somewhat different situation than above in that SCA presents a special situation. Also, there is wide agreement among AgriLife entomologists that different additives are merited (DowAgro agrees), but this information is not on the label, so you would need to relay this to your applicator to ensure they can follow best recommended practices.

Ready On-line Access to Chemical Labels for Agricultural Production

Herbicides, insecticides, seed treatments, fungicides, etc. All in one place. Chemical Data Management Systems maintains current full and Section labels at http://www.cdms.net (click on Label Database, then type in the name of the chemical in the search box). For additional use of this website, including instructions on how to search for chemicals by active ingredient (often a generic), consult the AgriLife Extension guide for using CDMS’ website at http://lubbock.tamu.edu/files/2015/05/2015-Texas-Grain-Sorghum-Weed-Control-Guide-A.pdf

An Important Component of Weed Control that Doesn’t Involve Chemicals, Equipment, or even Weeds

This tip was provided by:

Calvin Trostle, Extension Agronomy, Lubbock, 806-746-6101, ctrostle@ag.tamu.edu

Statewide

An Important Component of Weed Control that Doesn’t Involve Chemicals, Equipment, or even Weeds. I. Your Employees

I believe applicator awareness is often overlooked in weed control. Communication and the needed instruction between a farmer and their own employees can make the difference in a serious mistake that damages a current crop or affects a planned crop rotation next year, or perhaps amounts to 85% weed control instead of the near 100% that you otherwise would expect.

Here are some tips as you work with your on-farm weed control team…

- First, simply emphasize safety at all times. On the farm I grew up on, I will admit that didn’t always happen. I will admit that as a teenager I did some things that were stupid.

- Confirm and cross-check with your staff which chemicals and any additives are being used.

- Eliminate potential confusion about amount of chemical added to tanks, proper land speed, and issues involving calibration.

- Ride the rig with your staff as much as is needed to ensure they are properly trained.

- Communicate how important it is to fix plugged nozzles immediately (stop right there in the field!) and address other equipment issues; or in some cases that tank and system cleanout is conducted properly.

- Teach your staff to stop and CALL YOU if something doesn’t look right. Imagine one of your staff spraying dicamba on 16” tall grain sorghum with a hooded sprayer. But the ground is rough and at the speed you are calibrated for the hoods are banging into the ground. Instead of calling you, your employee raises the hoods 6” and sprays the field. Now you have the risk that some crop loss may occur due to unacceptable contact of dicamba with the sorghum and potential blasted heads which don’t fill very well.

Asking confirmation questions of your staff—there is a right way to do this…

A good way to double-check with your staff that proper chemicals and amount are being prepared for application is to ask what has been done. But how you ask will give you a more accurate indication of proper procedure and more likely identify if mistakes have been made.

Here is an example where you instruct your son/daughter or other employee to add a given amount, 2.0 gallons, of dicamba to a 300-gallon tank or spraying grain sorghum. Now you want to ask if they did it right.

- This is not a good question to ask: “Did you add 2.0 gallons of Banvel to the tank?” Why is this not a good question to ask?—because the employee can answer ‘Yes’ without revealing if they might have made a mistake. Maybe they did make a mistake. They added 2 jugs of Banvel (2.5 gallons each) to the tank. An employee might realize they made a mistake and be afraid to admit it (even though the long-term consequences—severely damaged sorghum—are worse; but they might not know this could be a problem, or they will only be working for you through the summer then quit and go back to school, etc.). This question may not have revealed the error.

- Instead ask this question: “What chemical and how much did you add to the tank?” Now this is a question they can’t answer ‘Yes’. They have to tell you something. They will either guess (still might be right, but not likely), or they don’t know, or they will tell you the wrong thing. Now you have a good chance of knowing if a mistake has been made. If the sorghum field hasn’t been sprayed yet, you can avert a potential disaster.

Investing time and training in your employee that handles spray duties, and rewarding them…

For your family member (even a teenager) or permanent staff that helps spray your crops:

- Have them study and train on your timeclock for their own pesticide applicator’s license.

- Arrange for them to take the test.

- When they pass it give them one-time bonus ($250?) or an annual supplement. This tells your employee he or she has increased value as part of your team and that you value their new skills. Increased training and sense of value on the part of your employee might avert a crucial mistake that could cost tens of thousands of dollars.

- Have your newly licensed applicator help you maintain your records for TDA.

In my next Sorghum Tip I will discuss some pointers for interacting with your custom applicator.

Ready On-line Access to Chemical Labels for Agricultural Production

Herbicides, insecticides, seed treatments, fungicides, etc. All in one place. Chemical Data Management Systems maintains current full and Section labels at http://www.cdms.net (click on Label Database, then type in the name of the chemical in the search box). For additional use of this website, including instructions on how to search for chemicals by active ingredient (often a generic), consult the AgriLife Extension guide for using CDMS’ website at http://lubbock.tamu.edu/files/2015/05/2015-Texas-Grain-Sorghum-Weed-Control-Guide-A.pdf