Recent High Plains Grain Sorghum Replanting

This tip was provided by:

Calvin Trostle, Extension Agronomy, Lubbock, 806-746-6101, ctrostle@ag.tamu.edu

High Plains

Recent High Plains Grain Sorghum Replanting

Starting the last week of June there was widespread storm damage on cotton and grains in the Texas High Plains, and a lot of cotton was lost. Numerous calls from producers noted the dilemma some felt about planting grain sorghum primarily due to sugarcane aphid concerns. Fortunately, among those that replanted to grain sorghum, finding a purported SCA-tolerant hybrid was a priority (glad you asked!), grain prices are up (some central South Plains, or Lubbock area, pricing now sets grain sorghum bu/A pricing = Dec17 corn), and many producers ultimately recognized that replanting grain sorghum was the right thing to do. Those growers that put two sugarcane aphid sprays in their budget probably overdid the expenses (though growers in the NW South Plains from last year have major damage fresh on their minds).

Be sure to review the SCA management guidelines outlined in the June 8 Sorghum Tip (have you watched the nine short videos yet?—now is a good time).

If you have late-planted grain sorghum or have replanted the crop…

Dicamba in Grain Sorghum

Dicamba (most commonly as Banvel or Clarity, but in many generics) along with 2,4-D have almost become anathema to many grain sorghum growers. Past experience of damaging the crop due to injury of twisting, rolled leaves, leaning, etc. that growers don’t like the appearance of and, yes, actual injury to the all-important growing point which can lead to significant loss of grain yield (blasting of heads). A grower in Lubbock Co. calling on Wednesday looking for quick options to control small pigweed (Palmer ameranth or carelessweed) assured me he knew full well the potential injury from dicamba.

But many of the errors of dicamba and 2,4-D injury can be attributed to diverging from the label. I have written before in Sorghum Tips the connection between the label timing of dicamba (and 2,4-D) applications and growing point differentiation, i.e. once grain sorghum is past about the 5-leaf stage (actually probably 6-leaf stage) or 8” tall, dicamba must move to drop nozzles or hooded sprayers, and all applications completed by 15” tall. This stage of growth at 5 & 6 leaf is before the head starts to form. After that, head injury may occur with over-the-top sprays, but you won’t know until the head emerges and begins to flower (or not). Otherwise, dicamba at 3-5 leaf stage (label recommendation) is still a good broadleaf weed control option, especially in the face of herbicide tolerant weeds. You know this if you are a cotton farmer in the Texas High Plains as over 60% of the cotton planted this year is some type of dicamba-tolerant (Extend) variety.

Furthermore, since there is so much dicamba-tolerant cotton in the area, the risk of off-target drift is reduced. The above farmer noted there was no non-dicamba cotton within at least 1.75 miles of the field he called about spraying dicamba on grain sorghum. Also, consider whether some of the physical drift minimization technology (spray tips, etc.) developed and recommended for use in dicamba and 2,4-D tolerant cotton might help you manage any dicamba and 2,4-D use in your grain sorghum.

Extreme Heat and Sorghum Flowering

This tip was provided by:

Ronnie Schnell, Cropping Systems – Statewide, College Station, ronschnell@tamu.edu

Statewide

Extreme Heat and Sorghum Flowering

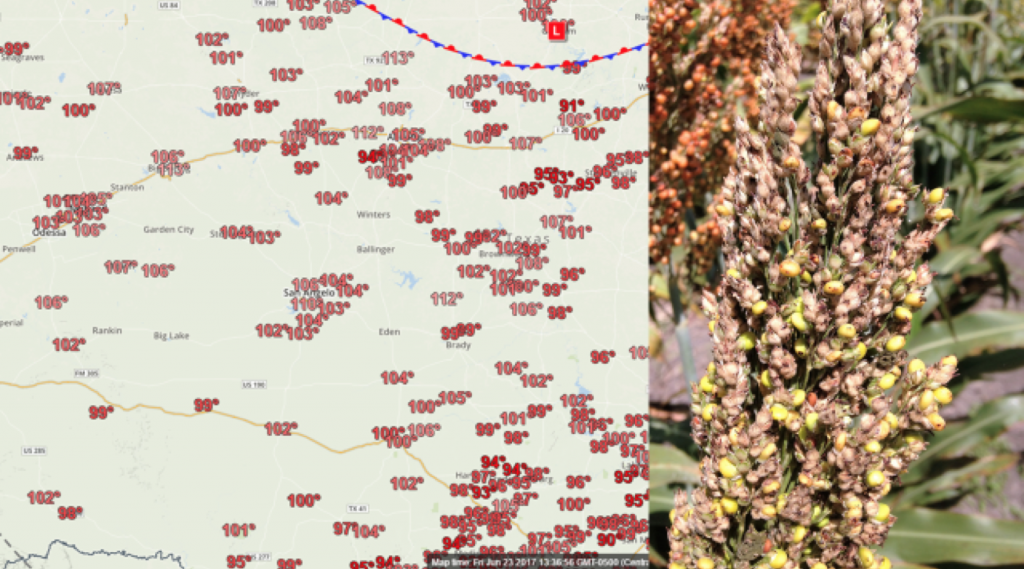

High temperatures have affected many portions of Texas in recent weeks and again during the current week. In some regions of Texas, grain sorghum was in critical growth stages that could be affected by high temperatures. Sorghum is known to have good heat and drought tolerance compared to many other crops. However, sorghum is sensitive to extreme temperatures.

Sorghum is sensitive to extreme temperatures during a 10-day period before and 15-day period after pollination. The period 5-10 days before flowering is critical for final floret development. The period 5 days before to 5 days after flowering is also sensitive. It is during this time that pollen shed, fertilization and embryo formation occur. Floret viability, pollination and embryo development can be reduced by temperatures from 97 to 100°F. Some hybrids are more tolerant to heat stress than others. Heat stress during grain set can reduce grain weight. Timing and duration of heat will determine the final impact on yield. Several days of extreme heat (>100°F) or many consecutive days of moderate heat during critical growth periods may result in some yield loss.

Avoidance is the about the only way to manage heat stress in sorghum. Early planting and choosing hybrids with maturity appropriate for your environment are the best to avoid heat stress in Texas. Also, pay attention to hybrid performance trials in your region. Hybrids that consistently perform well in your region are likely better adapted to handle biotic and abiotic stresses encountered in Texas.

Ensuring Later-Planted Sorghum Growers have Sugarcane Aphid Resources

This tip was provided by:

Calvin Trostle, Extension Agronomy, Lubbock, 806-746-6101, ctrostle@ag.tamu.edu

Statewide

Ensuring Later-Planted Sorghum Growers have Sugarcane Aphid Resources

For grain sorghum planted since mid-April in the Concho Valley, North Texas, and the High Plains, the good news is that it appears the downstate reports of sugarcane aphid are still well distant. The longer this remains the better. For this planted sorghum as well as forthcoming High Plains sorghum the “First Things” SCA information from Texas A&M AgriLife entomologists are below. Though you may be concerned about cost of treatment—and these management guidelines emphasize the need for treatment when thresholds are met—you can reduce the potential that those costs spin out of control (money you spend on another spray; the money you lose on a damaged crop) by appropriate scouting and timely spraying. One of our High Plains AgriLife Extension IPM agents, Kerry Siders (Hockley/Cochran/Lamb Counties) has noted “A good first shot can eliminate the need for a second spray.”

- Current SCA control recommendations from AgriLife Extension entomology colleagues. This includes the “Scout Card” at http://lubbock.tamu.edu/files/2016/03/ENTO-047.pdf (recommendations unchanged from 2016). There has been a move within AgriLife to reduce the aphid thresholds downstate to the lower SCA numbers in line with High Plains recommendations.

- Texas Sugarcane Aphid News blog at http://txscan.blogspot.com/ Of particular interest on the blog, scroll down to the Feb. 20, 2017 entry which lists 9 AgriLife videos (41 minutes total) pertaining to all aspects of SCA. I highly recommend all sorghum producers in the High Plains take an hour to view these.

- Other SCA and sorghum insect management info. is found at http://www.texasinsects.org/sorghum.html,

Scouting for Sugarcane Aphids

This tip was provided by:

Ronnie Schnell, Cropping Systems – Statewide, College Station, ronschnell@tamu.edu

South and Central Texas

Scouting for Sugarcane Aphids

Sugarcane aphids are currently found in many sorghum fields in the southern and coastal areas of Texas. The distribution of the aphid is expanding north into central Texas. Sugarcane aphid distribution is being tracked at: https://www.myfields.info/pests/sugarcane-aphid. This map shows where the aphid has been detected but not the level of infestation.

Many fields have been sprayed in the Rio Grande Valley and Coastal Bend. Some fields in the upper Gulf coast are reaching threshold and will require treatment. It is important to scout frequently and thoroughly once aphids are detected. Recommended scouting methods differ for south and central Texas compared to the High Plains region of Texas. Specific recommendations can be found at: https://www.myfields.info/sugarcane-aphid-texas-sorghum-0

When scouting, make sure to identify the aphid. Yellow sugarcane aphid, corn leaf aphids or greenbugs may be present. Thresholds and control methods will differ for these pests compared to sugarcane aphids. If chemical control of sugarcane aphids is needed, keep in mind pre-harvest intervals and spray restrictions. Transform cannot be used from 3 days pre-bloom until after seed set.

If you have planted hybrids with resistance or tolerance to sugarcane aphids, keep in mind that the hybrid is not immune to sugarcane aphids and needs to be scouted. Sugarcane aphid populations may take more time to reach economic threshold, if at all.

West Texas & Early Planting to Minimize Potential Sugarcane Aphid Impact

This tip was provided by:

Calvin Trostle, Extension Agronomy, Lubbock, 806-746-6101, ctrostle@ag.tamu.edu

West Texas

West Texas & Early Planting to Minimize Potential Sugarcane Aphid Impact

United Sorghum Checkoff Program agronomist Dr. Brent Bean notes caution about planting grain sorghum too early. Producers by now across Texas have heard from AgriLife entomologists to “plant outside the normal” window, which is primarily “plant early” to reduce your potential exposure to sugarcane aphid, especially when plants are at the vulnerable seedling stage. That stage-of-growth vulnerability should be partially covered by recommended insecticide seed treatments.

Dr. Bean notes that early planting is not without question. Yes, you can plant too early thus grain sorghum is slow to germinate, slow to emerge, and may not provide you the protection you expected.

“There are reasons why optimum planting dates for sorghum exist, and these should not be ignored. Optimum planting dates are based on soil temperature, timing of seasonal rainfall and daily maximum temperatures, risk of insect infestation, and length of growing season,” Dr. Bean notes.

In the High Plains region over the years, millions of dryland sorghum acres have been planted after May and June rainfall. The outcome is May-June rainfall charges deep soil moisture then September rains (the second wettest month of the year in most West Texas counties) carry the crop through to maturity.

Grain Sorghum Germination and Soil Temperature

Again Dr. Bean notes, “One of the first considerations for early planting should be soil temperature. The cooler the temperature the slower the sorghum will germinate and emerge. Most agronomists suggest waiting to plant sorghum until the minimum daily soil temperature is 60°F (usually 2-4” depth) and the forecast for the next 10 days is for warm weather.” Slightly cooler temperatures may be sufficient provided the weather is clearly warming.

How does the above sorghum germination temperature compare to cotton? The optimum planting target for cotton is a 10-day average soil temperature (not minimum) of 65°F at the 8-inch depth. Sixty degrees for sorghum is likely a more shallow temperature, and that is a minimum. A 4” depth, there is some daily fluctuation, but this would point to an initial sorghum planting temperature that is probably 7-10 days earlier than cotton.

Another safeguard against too-early grain sorghum planting: do not plant grain sorghum any earlier—regardless of soil temperature—than the point which is two weeks after your last average 32°F temperature. So, if your county’s last 32°F is April 3 (Dawson Co.) then do not plant sorghum any sooner than April 17—BUT ONLY IF soil temperatures are adequate (the West Texas Mesonet reports the Lamesa April 13 bare soil temperature minimum at 4” is 61°F, but that could be due to April 12 rains).

Here are these last average 32°F dates for selected West Texas counties:

Tom Green, March 28 Yoakum, April 5 Gray, April 13

Taylor, March 24 Lubbock, April 6 Moore, April 18

Wilbarger, March 30 Swisher, April 14 Ochiltree, April 25

Collingsworth, April 1 Bailey, April 17 Dallam, April 23

Dawson, April 3 Deaf Smith, April 19

So, early sorghum planting to minimize potential exposure to SCA is probably not worth the risk a poor or slow growing stand. Companies may have hybrids that have tolerance of cooler soils, but then you may lose proven yield potential and/or your possible SCA tolerance in the hybrid.

Early planting may also reduce the risk of other insect damage. In most regions, headworms and midge issues are much less with early planting. From a SCA management standpoint this is important because many of the insecticides used for these two pests will cause SCA populations to flare.

In summary, Dr. Bean notes early planting of sorghum for managing SCA is an effective IPM tool and should be considered. “However, do not disregard sound sorghum agronomic practices. Simply moving the planting date up by a couple of weeks can make a significant difference in managing SCA.”

Planting Grain Sorghum: II. In-row Spacing

This tip was provided by:

Calvin Trostle, Extension Agronomy, Lubbock, 806-746-6101, ctrostle@ag.tamu.edu

Statewide

Planting Grain Sorghum: II. In-row Spacing

In a previous Sorghum Tip, I discussed row spacing (see http://texassorghum.org/sorghum-tips Feb. 20, 2017). Now what about spacing of seeds within the row?

On this smaller scale of about two to six inches within the row, it may seem that the uniformity of spacing is not that important. Yes, it is true that the root system, for example, will basically still explore the same area and leaf area will be about the same. Some hybrids, though, do respond differently to spacing around the individual plant with more tillering than others. This can be a positive effect (a plant accounts for extra space and yield potential by tillering to compensate for a gap in the row) and negative (excess tillering is not desirable in moisture-limited production). Research beginning in the early 2000s from Dr. Bobby Stewart’s program at West Texas A&M demonstrated that for West Texas dryland conditions suppression of tillering by placing 4 to 6 seeds (thus subsequent plants) within 1.5” or less would essentially eliminate tillering. Resulting yields tended to be higher (the plant does not direct resources into unproductive tillers) than uniform spacing, but the potential for less shading of soil of clumped plants may lead to more weeds and higher evaporation of soil moisture.

Still having uniform spacing with the row is a plus. We are most immediately concerned about larger gaps of 12” or more—they are obvious, especially if you are planting 3 to 6 seeds per foot of row. But the same principle applies like I discussed in row spacing, uniformly distributed plants is favorable.

The faster you plant on rough ground you will also lose incrementally some of your uniform spacing in the seed drop. I am not the first one to advise producers to “slow down” when you are planting.

I have already planted my grain sorghum. I will consider this next year…

Actually, when your crop is young, it is a good time to evaluate the stands you have in individual rows. Do you have skips? Do you have a row that looks thick? Or thin? Usually you can tell from the tractor tire track ribs which direction the planter was moving so you know which row unit of the planter may have thickly or thinly seeded row. The planter unit needs to be checked for a malfunction. If you are using a plate planter you can’t expect quite the uniform spacing (or even favorable control of seed drop), but for planters that meter seed in an air-vacuum system, you should expect all rows to very closely drop the same number of seed. And if you see a row that departs from the general appearance, you need to check that planter unit.

Planter Unit Seed Drop Confirmation

In testing on a late model John Deere 8-row planter at one of our AgriLife research facilities, I found that two rows dropped 17% or more seed than they should have, and one rows was -20% from what was targeted. Pending the production conditions this creates a potentially non-agronomic plant population. I recommend that farmers, once they have their seed on hand for grain sorghum—or any other crop—set the planter up, turn the drive wheel a set distance and catch seed to calculate the number of seeds per foot. How does this match with your planter book? In this case, a correction can be made before you go to the field, otherwise you await the stand to see if one of your planter units may be off. For an individual row with the seeding rate off, that is like having the whole field at that population in that row. You have too many or too few plants. It needs to be corrected.

Sugarcane Aphid Management Suggestions & Resources

This tip was provided by:

Calvin Trostle, Extension Agronomy, Lubbock, 806-746-6101, ctrostle@ag.tamu.edu

Texas High Plains

Sugarcane Aphid Management Suggestions & Resources

This edition of Sorghum Tips deals with SCA management in the Texas High Plains. The information may also be relevant for the Concho Valley and Rolling Plains, though the information presented here was not developed in those regions. There are differences in the High Plains recommendations vs. what we published in the March 3, 2016 Sorghum Tips for South & Central Texas (see http://texassorghum.org/sorghum-tips for Extension’s Dr. Robert Bowling’ comments).

Instead of reproducing here the details of current SCA recommendations for Texas High Plains grain sorghum, I refer you to the direct writings of Texas A&M AgriLife Extension’s High Plains entomology group led by Dr. Pat Porter, Lubbock. Consult the Texas Sugarcane Aphid News blog at http://txscan.blogspot.com/ The March 2 posting is the first installment of advice with the topics:

- Sugarcane aphid will most likely return at some level for renewed infestation of High Plains grain sorghum, so be prepared and plan for it.

- Beneficial insects cleaned up the overwintering aphids in 2016, but what does this mean (or not mean) for 2017? Read about early observations on the level of current beneficial insects observed in wheat.

- What about 2017? Certainly, early planting remains a primary consideration. Late planting in 2015 was also a good strategy, but that didn’t hold in 2016.

- Seed treatments are cheap insurance. It appears that 45 days of protection can be obtained with neonicotinoid seed treatments. This is especially helpful for seedling sorghum, but all sorghum regardless when planted, should use this strategy.

- “Resistant” or “Tolerant” grain sorghum hybrids are still susceptible. No grain sorghum hybrids have been shown to be able to keep SCA numbers below treatment thresholds, but they can slow the rate of SCA population increase. All of these hybrids require scouting.

- Additional information for SCA will be posted to the Sugarcane Aphid Network blog soon for the Texas High Plains. Further topics will include initial treatment thresholds, insecticide rates and efficacy, and economic thresholds for a potential second spray. Remember, High Plains SCA thresholds are lower than South Texas based on research to date.

Sugarcane Aphid Management Videos for the Texas High Plains

The Texas A&M AgriLife Extension entomologist team working on grain sorghum (Porter, Bynum, Reed Kesheimer) posted nine videos ranging from 3 to 8 minutes in their February 20 update. See them all at http://txscan.blogspot.com/ Topics include early planting, “resistant” hybrids, thresholds, timing, insecticides to prevent sticky harvest issues, SCA effects on forage stalk quality, etc.

Sugarcane Aphid: Update, Outlook, and Early Season Thoughts on Management

This tip was provided by:

Robert Bowling, Extension Entomology, Corpus Christi, (316) 946-0329, robert.bowling@ag.tamu.edu

South Texas

Sugarcane Aphid: Update, Outlook, and Early Season Thoughts on Management

Sugarcane aphid is building populations on overwintering hosts from the Lower Rio Grande Valley up through the Coastal Bend of Texas. Dry conditions and unusually high temperatures in the Valley have allowed farmers to get a big jump on seeding the 2017 sorghum crop. Sorghum seeded early in February has emerged and conditions are favorable for rapid growth—also favorable for an early-season infestation by SCA. This may be a harbinger of things to come for south Texas sorghum producers.

It is too early to say with certainty SCA will pose more an issue for sorghum producers in the Valley (and for south Texas) in 2017 than in 2016, but it is always a good idea to scout sorghum early and often for early aphid detection. An insecticide seed treatment will provide approximately 30 to 50 days of protection from the planting date against SCA. Start monitoring sorghum about three weeks after planting for early detection of SCA, for early season infestations which usually start on field edges especially where overwintering hosts such as volunteer sorghum or Johnsongrass are present. Always check field borders for SCA.

Many sorghum producers are moving toward sorghum hybrids with ‘high tolerance’ to sugarcane aphid. Many of these hybrids in multi-state university testing programs have demonstrated their value when compared to an SCA susceptible hybrid. Sugarcane aphids can be found on ‘highly tolerant’ sorghum hybrids, but their population growth is much slower than growth on susceptible hybrids. Regardless, all sorghum should be routinely scouted for SCA. Check with your seed rep before purchasing any sorghum hybrid. They will have the knowledge of each product’s performance potential and placement not only within a region but within fields on your farm. A list of sorghum hybrids for 2017 that have been identified as having sugarcane aphid tolerance is posted by United Sorghum Checkoff Program, http://www.sorghumcheckoff.com/farmer-resources/grain-production/hybrid-selection (From the 2016 list of 21 hybrids, 15 remain, six have been deleted, and 12 new hybrids were added for 2017, as of Feb. 28.)

Keep in mind that you are paid on pounds of grain produced and not the tolerance of your hybrid to sugarcane aphid. We would not suggest abandoning a high performing SCA susceptible hybrid for an unproven hybrid with SCA tolerance. Remember that SCA management is highly dependent on early detection and routine weekly or twice weekly scouting to treat when populations reach an economic threshold of 50 to 125 aphids per leaf (average of sampled plants; remember, this is a South Texas threshold, the threshold for the High Plains is lower). Treatment must be applied within 3 to 5 days of reaching a threshold to prevent populations from reaching economically damaging levels. Remember that carrier volume is extremely important to maximize penetration of the insecticide into the canopy (10-15 gallons/A by ground and 5 gallons/A by air).

Fungal Infection of Sugarcane Aphid, South Texas, 2016

I recently wrote about an epizootic fungus occurring in an insecticide efficacy trial in 2016 which colonized sugarcane aphids. The fungus responsible was Lecanicillium lecanii. Is this possibly a means of managing SCA? Although epizootic fungi are highly effective for SCA (and other pests) management, their occurrence is very dependent on very specific parameters. At this time, our observations on this fungus are limited to a small area of Texas in 2016. It remains to be seen if it will be present let alone have an impact on Texas sorghum in 2017. Currently, it is not clear if the fungus could be managed by producers for control of SCA. For further reading on the fungus, see newsletters 1.7 & 2.1 at http://betteryield.agrilife.org/newsletters/

For more information on sugarcane aphid and other sorghum pests in South Texas please visit our website at http://betteryield.agrilife.org.

Planting Grain Sorghum: I. Row Spacing Width

This tip was provided by:

Calvin Trostle, Extension Agronomy, Lubbock, 806-746-6101, ctrostle@ag.tamu.edu

Statewide

Planting Grain Sorghum: I. Row Spacing Width

The average Texas grain sorghum field has narrower row spacing than 20 and 30 years ago. The impetus to do so incudes better understanding of plant growth response, improved sorghum shading of the soil for reducing evaporation and suppressing small weeds, more conservation tillage, and in some cases the desire to push for higher yields with more uniformly spaced plants. And finally, when sorghum producers (as well as corn, cotton, and other crops) push for higher yields there is a common belief that higher plant populations may enable you to realize that most years. But as any Texas farmer knows, weather varies from year to year, and a crop will not respond the same way each year. Higher plant populations can limit your sorghum’s ability to respond to environment, especially rainfall.

Whether a farmer moves from 40” rows to 30” rows in the High Plains, from 36” or 38” rows to 30” in South Texas, or to 15” or 20” row spacing anywhere in the state, there is tendency to increase seed drop thus resulting in a higher population. I tend to believe this increased seed drop is a neutral to negative effect in most Texas sorghum fields because many farmers are in fact already at the upper end—or beyond—what seed drop they should be using (see below where to get AgriLife suggestions). I recommend that farmers initially do not increase seed drop when they reduce row spacing width. Instead, let the more uniform spacing of plants in the field be your friend and potentially increase your yield. That alone is likely an improvement in agronomic practices.

I will cover in-row spacing in a future Sorghum Tip.

What if I am drilling my grain sorghum?

Some Texas sorghum farmers, at least in the High Plains, may even drill their grain sorghum. Compared to 30” rows or even 40” rows, should they increase their grain sorghum seeding rate? I usually say ‘no.’ First, it is hard to set drills to plant a targeted seed drop. They are designed to plant seed in volume, like wheat. You may not be able to get a sorghum seeding rate low enough without taping off 1 in 3 drill rows, or even 1 in 2 drill rows. Again, let the spacing of your seed and the subsequent plant be your friend. I will concede, though, a 10% increase in seeding rate if drilling due to the inferior ability of a drill to place seed like a planter does. If the ground is rough and thus seedbed planting conditions are less than desirable, I might increase seeding rate 20%, but know that if you get the rain you hoped for, all the seed could germinate, and you are immediately overpopulated.

What grain sorghum seeding rates should I be using?

In some areas of the state we truly don’t have good data, or it may be 30 or more years old. We don’t discount the data from the distant past, but as hybrids have changed some, tillering ability may be different, etc. it would be good if AgriLife could bring you recent multi-year and multi-site data for each region of the state. For our current general suggestions see the United Sorghum Checkoff Program pocket grain sorghum production guides at http://www.sorghumcheckoff.com/farmer-resources/grain-production/ There are three editions that cover Texas (South & Central Texas; South Plains/Concho Valley/Rolling Plains (the West Texas edition), and a third edition that covers the Texas Panhandle. The former two guides were prepared by Texas A&M AgriLife staff, the Panhandle edition was a joint effort between Texas A&M and Kansas State.

Preplant and Preemerge Herbicide Options in Grain Sorghum

This tip was provided by:

Ronnie Schnell, Cropping Systems – Statewide, College Station, ronschnell@tamu.edu

Statewide

Preplant and Preemerge Herbicide Options in Grain Sorghum

Early competition from broadleaf and grass weeds in grain sorghum can result in yield loss. Use of soil active herbicides applied before planting or before sorghum emergence is critical for effective weed management. Below is a partial list of herbicide options and approximate cost at low and high labeled rates. Prices are for planning purposes only. Actual cost may vary. Always read and follow label directions for specific rates and timing. EPPS = early preplant surface, SPPI = shallow preplant incorporate, PRE = after planting but before crop emergence.

- atrazine – (AAtrex, Atrazine 4L) $5-10/A

- 1-4 pts/A, PRE only (TX Gulf Coast & Blacklands only)

- Lower rates (1-2.5 pts/A) for Pigweed control in other regions.

- Supplemental Label can be found at:http://www.cdms.net/ldat/ld280000.pdf

- Good control of broadleaves and some grasses.

- Do not apply to coarse textured soils or soil with less than 1% organic matter.

- Be aware of rotation restrictions.

- saflufenacil (Sharpen) $6-14/A

- 1-2 oz/A EPPS or PRE

- Burndown herbicide with some residual activity

- Good activity on broadleaves.

- 2-4 weeks of residual, some hybrids may be sensitive.

- dimethenamid-p – (Outlook, Establish) $11-23/A

- 12-21 oz/A based on soil texture, EPPS, SPPI, PRE

- Seed Safener (Concep) Required.

- Good control of grass and broadleaf weeds.

- s-metolachlor – (Brawl, Medal, Dual II Magnum, Brawl II, Cinch, Medal II) $10-28/A

- 1-1.6 pts/A applied EPPS, SPPI, PRE

- Seed Safener Required.

- Good control of several annual grasses.

- acetochlor – (Warrant) $13-27/A

- 1.5-2.5 qt/A SPPI, PRE

- Seed Safener Required.

- Annual grass control and some broadleaves.

- mesotrione – (Callisto) $36-39/A

- 6-6.4 oz/A EPPS or PRE

- Good broadleaf control.

- Add a surfactant or crop oil for control of emerged weeds

Pre-Mixes (products requiring safener (Concep) in red)

- dimethenamid + atrazine (Establish LITE, G-Max LITE) $11-23/A

- s-metolachlor + atrazine (Bicep II Magnum, Charger Max ATZ, Cinch ATZ) $16-26/A

- saflufenacil + dimethenamid (Verdict) $18-34/A

- s-metolachlor + mesotrione (Zemax) $42/A

- s-metolachlor + mesotrione + atrazine (Lumax) $51/A